Tag: #woodworking (6 posts)

Building a Backyard Chicken Coop in the City

Back in 2018, we decided to raise chickens in our urban backyard, all in the name of being able to have fresh eggs every morning. Our city had bylaws on having chickens, which included:

- A maximum of 4 hens (no roosters), 4 months or older

- Ducks, turkeys, or other livestock are not allowed

- Eggs, meat, and manure cannot be used for commercial purposes

- Backyard slaughtering is not allowed

Since we were fortunate enough to have access to a backyard at the time, we decided to build a coop and start the lifestyle of having easy access to fresh eggs. Was it cost effective? Heck no, but it sure was a fun journey!

Wooden Phone Stand

Phone stands are something that seem a little unnecessary, but once you have one then you’ll wonder how your desk lived without one. I’m a firm believer in having a dedicated place for everything as a solution to keep things tidy, so making a phone stand for my desk at work just made sense.

I started off on Google to look for existing designs I could imitate, but most fell short of not fitting my aesthetic needs. I wanted a balance between simplicity and form, without requiring too much effort to make. I eventually came across one design by Woodenlife on Artfire and deemed it the winner for my copy-cat woodworking. I sketched out the side profile in SolidWorks, pasted it on to the wood block, and proceeded to cut it out on my bandsaw.

Making Do With a Bargain Bin Bandsaw

It’s generally known that cheap tools are usually not worth the trouble, but the deal on this bandsaw was simply too hard to pass up. With only a missing table, it was merely a quick woodworking project away from restoring its full functionality.

New Workshop + Plywood Bench Stool

My family moved into a new house, meaning that we finally have an actual garage instead of a measly carport. But what this really means is that I get a chance to claim space to set up an actual workshop! First project was naturally a workbench, which I put together using 2x4’s and a 3/4" MDF board for the work surface (see above). Second project was a bench stool, as shown in the following images below. The builders left some 1/8" plywood in the yard, and I wanted to see how sturdy of a chair I can make with it given the inherent flimsiness of the thin sheet stock. By adding a reinforcing cross-brace at the base of the legs, I was able to significantly increase its sturdiness.

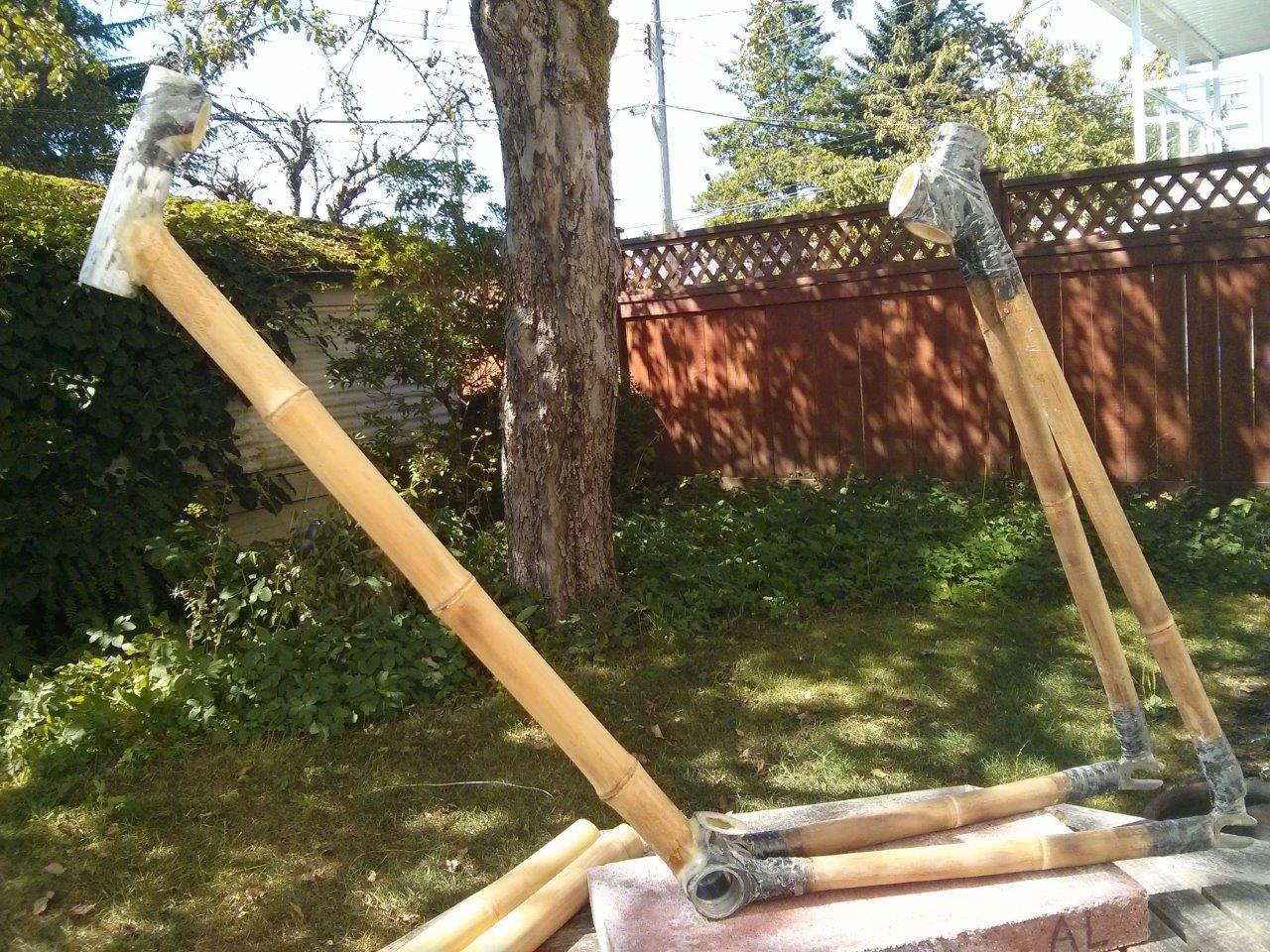

Boo-Boo with the Bamboo Bike

As you probably already know, I made a bamboo bike which I’m very proud of. However, what you probably don’t know is that I made some mistakes in the process. The photo above shows the result of one of these progress speedbumps, and yes, I did indeed cry the day I had to cut those tubes out.

I started this project in November 2013 but failed to finish due splitting bamboo. Progress was moving forward: I had the bamboo, carbon fibre, and epoxy ready for frame building, and the poles were in the process of being cut and shaped to size. However, winter was quickly approaching and the weather was becoming less and less ideal for carbon fibre layup. The epoxy I was using had a working temperature above 10°C, but the outside temperature was beginning to drop below that. I was able to keep it in its liquid state by using my mother’s hair dryer (don’t tell her though since she still doesn’t know…), but the epoxy wasn’t the main issue. Apparently bamboo is a living thing and doesn’t like drastic changes in temperature. Turns out doing the layup in colder temperatures, then bringing the frame inside to dry in warm, livable temperatures wasn’t good for the bamboo. Moisture is the devil here, and causes the wood to expand and contract based on the current environmental conditions.

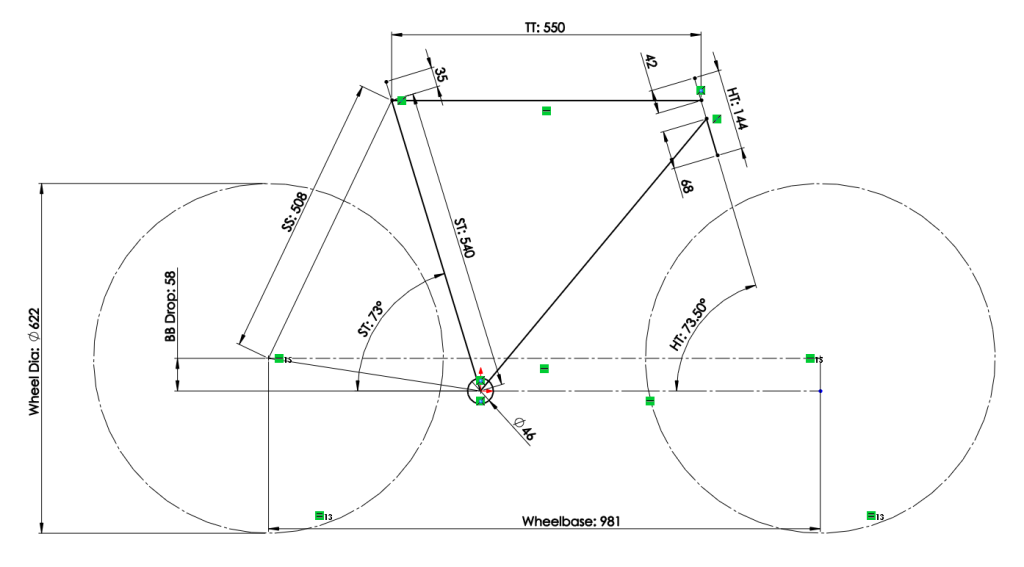

Award Winning Bamboo Bike

Objective: Exceed the Vancourite-hipster threshold by building a fixed-gear bicycle using bamboo and carbon fibre.

Challenges:

- Constructing a frame jig to allow freedom around joints for carbon-fibre layup

- Accounting for the non-uniformity of bamboo poles at the frame lugs

- Maintaining compatibility with standard bicycle components

- Ensuring the frame is treated for typical"Wet" Coast weather

Awards:

- First Prize - Hand Tools Only Instructables Contest

- First Prize - Teach It! Instructables Contest, Sponsored by Dremel